Information

Hotline

(86)21-66080773TEL:+86-527-86788888

FAX:+86-527-86782059

EMAIL:jlsl@jlsj.cn

ADDRESS:Songshan North Road 33, Sihong Developing Zone,jiangsu,CHINA.

The first quarter, second BOPE development applications

Speaker: Dr. Gaudali; collate people: excellent Yu Dao Liang Gao Gong.

Beijing Research Institute of Chemical Industry was founded in 1958, formerly under the Ministry of Chemical Industry, and entered the China Petrochemical Corporation in 1998. Its business mainly includes ethylene technology, synthetic resin, synthetic rubber, organic fine chemical industry and chemical environmental protection. In the synthesis of resins, it is mainly responsible for the development of new materials for synthetic resins of Sinopec and the vast number of Sinopec Sinopec. Customers provide quality service.

The special material can be produced on the existing BOPP double-pull production line, which fully meets the requirement of raw material stretching film forming. This also makes the large-scale industrial production and application of BOPE possible.

In terms of mechanism, the development of BOPE special material is a kind of high performance film which is produced by taking the molecular structure of polyethylene as the guide and combining with advanced double-drawing processing technology. The traditional PE film is processed by extrusion blow molding and extrusion casting technology. Blowing and casting is a kind of melt processing, so the molding process. In the unsteady state, the BOPE film, like BOPP, is stretched by the flat film method, that is, the casting is extruded first and then the casting is stretched again after the second preheating and then the casting is stretched into the film under the semi-solid state. The forming process is a steady-state structure, so the film orientation is higher, especially the thickness uniformity is better. However, the existing polyethylene materials do not have the required molecular structure and can not be biaxially stretched.

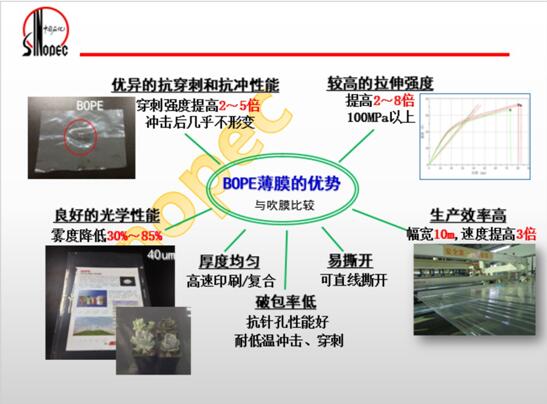

Because of its high orientation, molecular weight orientation and crystalline orientation, excellent impact resistance and anti-puncture properties, the puncture strength is about 2-5 times higher, especially after impact deformation is very small.

The tensile strength is higher than that of the existing blown film. The tensile strength is 2-8 times higher than that of the existing blown film. The two directions can reach more than 100Mpa.

BOPE is a rapid cooling process. The crystalline structure is fine, so the optical properties of BOPE film are good, and the fog of BOPE film is reduced by 30% - 85%, so it has very excellent optical properties.

Flat-film stretching has good thickness uniformity, which is suitable for high-speed printing and high-speed composite. In addition, BOPE film also has a certain tearability.

To sum up, BOPE film has these advantages, in packaging applications, because it has better pinhole resistance, low temperature impact resistance and puncture, can effectively reduce the breakage rate, for manufacturers to reduce costs.

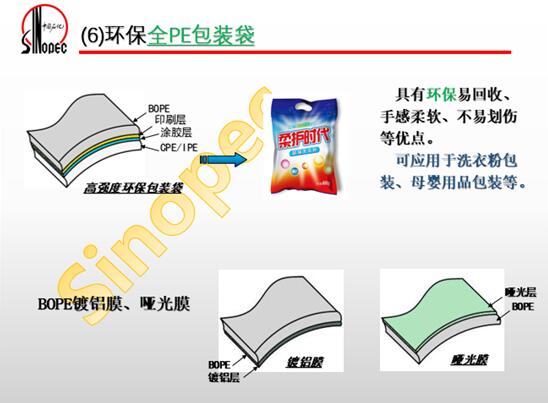

At present, BOPE film has been used in daily chemical packaging, food packaging, agricultural film and other fields, and achieved certain results. The developed BOPE film applications include heavy packaging bags, food packaging, composite bags, daily chemical bags, white film and so on.

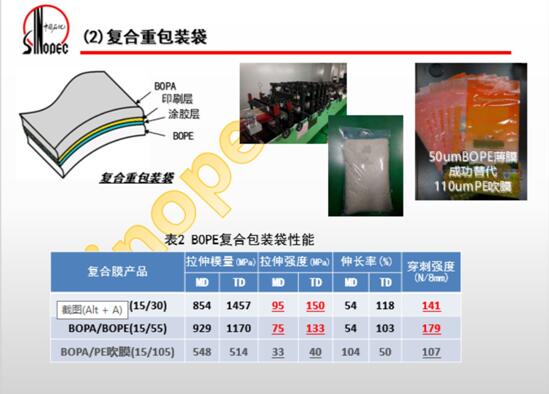

Among them, the application of BOPE composite bags in this area is relatively successful, mainly using BOPE as a layer through the composite as a package material, the packaging material has the characteristics of sprint resistance, impact resistance, high strength, low temperature resistance. Because the high strength of BOPE provides the possibility of packaging material thinning, thinning the existing packaging, and at the same time improving the packaging strength can reduce the breakage, reduce the waste of packaging, reduce costs, we think that reducing the amount of plastic, thinning, but also as a more practical packaging green environmental protection technology.

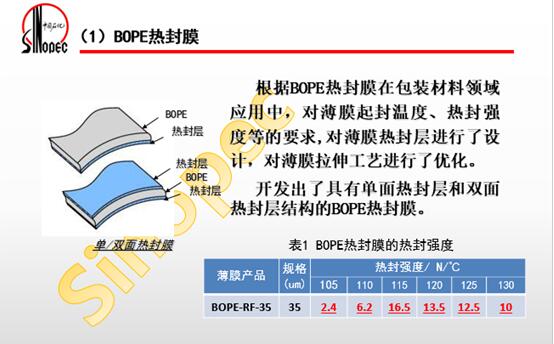

1. Development of BOPE thermal sealing film: According to the requirement of BOPE thermal sealing film in packaging material field, the thermal sealing film was designed and the stretching process was optimized. BOPE heat sealing film with unilateral thermal seal and double-sided thermal seal structure has been developed. At present, the thermal sealing strength of the heat sealing film developed is relatively high, and the highest sealing temperature is above 20N.

By comparing the properties of BOPE composite heavy packaging, we can see that the tensile strength and puncture strength of the two key indicators of packaging are 30um BOPE composite 15um BOPA, its tensile strength and puncture strength have reached or even exceeded 105um film blowing composite 15um BOPA structure, so for the package The loading strength has been greatly improved.

For this application, we have two designs. One is that BOPE is used as the intermediate layer, the top and bottom of the composite materials to make high-strength, anti-puncture packaging bags to replace some packaging intermediate layer with BOPA, the other is that BOPET/BOPE structure is used to replace BOPA/IPE (CPE) structure without barriers, not only to reduce costs. Instead of nylon, it can achieve certain thinning effect and has the easy tear property that the existing IPE does not have.

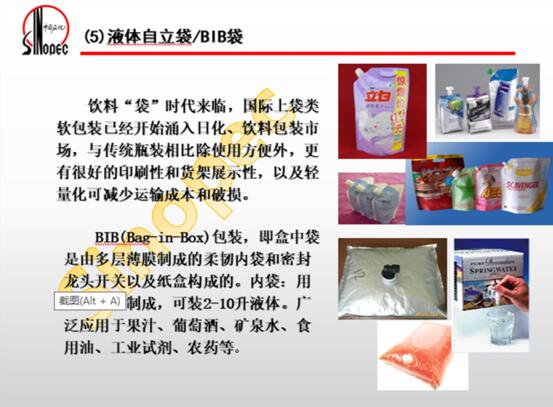

Now the trend of liquid packaging is to use self-contained flexible bags for packaging, BOPE has certain advantages in this respect. With the advent of the beverage bags era, the international soft bags have begun to pour into the daily chemical and beverage packaging market. Compared with the traditional bottle, it is more convenient to use, has better printing and shelf display, and lightweight can reduce transportation costs and damage.

BIB (Bag-in-Box) packaging, that is, the bag in the box is made of multi-layer film flexible inner bags, sealing tap switches and cartons. Inner bag: made of 2-10 litres of liquid. Widely used in fruit juice, wine, mineral water, edible oil, industrial reagents, pesticides and so on.

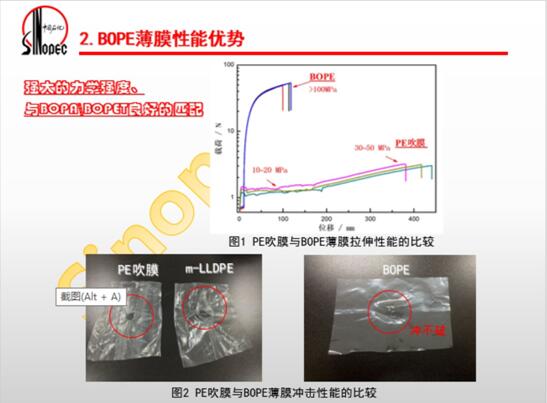

Mechanical properties: BOPE and PE blown film tensile curve above, existing PE blown film tensile yield at very low strength, about 10-20 Mpa yield, fracture strength 30-50 Mpa, but because of BOPE processing characteristics, processing process of tensile orientation, BOPE almost no yield, fracture strength can reach 100 Mpa, and extension The long rate and BOPA and BOPET have good matching, and the composite material has good synergy effect after packing.

Compared with BOPE film, the impact strength of ordinary PE film is lower, or the impact deformation is larger, but the impact deformation of BOPE film is smaller, without breaking, it does not affect the secondary use of packaging materials.

Show the properties of BOPE film industrial products: Comparing the main performance indicators of BOPE, the tensile strength, puncture strength, mist, impact strength of BOPE film have been greatly improved than the existing blowing PE film. The strength of 35um BOPE film can reach 105um PE blowing film strength and higher than the existing metallocene strength, so as a A new packaging substrate should have a good application prospect.

afterword

In order to promote the development and application of new materials and technologies, Sheng Chenglin, General Manager of Jiangsu Excellent Polymer Materials Co., Ltd, invited Dr. Dawley of Sinopec Research Institute of Chemical Industry, Mr. Zhang Guangqiang, General Manager of Foshan Plastic Technology Oriental Packaging Film Branch, Mr. Huang Junbiao, Executive Vice President of Shanghai Lingbo Plastic Packaging Co., Ltd. Professionals in various links of the industrial chain have held professional discussions on BOPE manufacturing and characteristics, and the application of sophisticated - Longpu Weixin Group.

This article is a speech by Dr. Goodall, a well-organized Wechat Event organized by Jing + Longpu. It is an integral part of the first phase of Jing's appeal for an environmentally friendly plastic packaging program. It was compiled by Jiangsu Jing Yu Daoliang Gaogong according to the pronunciation of Dr. Gao's speech. (the first quarter, second BOPE development applications).